FerroCheck

Spectro Scientific USA

Quick Enquiry

Ferrocheck 2000

Ferrous wear metal measurement in lubricants

Highlights

The FerroCheck 2000 is a portable magnetometer offering accuracy and convenience for total ferrous measurement of in-service lubricating oils. It takes less than 30 seconds, with just 1.5 ml of oil, to measure ferrous content in oil from single digit ppm up to 1%. The FerroCheck is sensitive to both small and large wear particles, making it an ideal screening tool in the field, as well as a complimentary tool for oil laboratories and on-site MiniLab Series products, for detection of large wear particles.

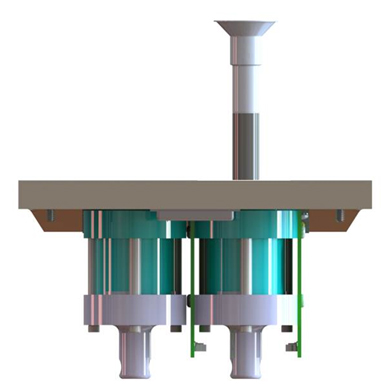

Principle of Operation

The core of the FerroCheck 2000 is a pair of precision rounded coils that when powered, generate magnetic fields. When a small amount of in-service oil is inserted into one of the coils, ferrous particles, such as Iron, Nickel, and Cobalt, as well as corrosion by-products such as FeO, FeSO4, and Fe2O3, interact with the magnetic field and introduce current changes in the coils. The amount of current change is proportional to the amount of Ferrous particles in the oil, calibrated by weight in parts per million (ppm).

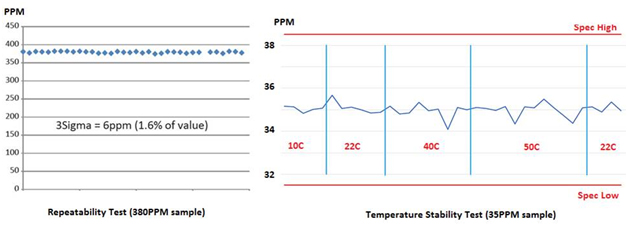

The vial that holds the oil is designed to optimize the position of the oil and the particles in the coil, as large particles tend to settle at the bottom of the vial. Before the measurement, the coils are automatically balanced electrically, removing the impact on measurement from ambient temperature variation. The result is repeatable and stable measurement regardless of operator and environmental temperature, which is critical for a large service team doing on-site oil analysis in the field.

Key Features

- Simple and fast, takes less than 30 seconds

- Use only 1.5 ml of oil with very little waste

- Accurate, repeatable and stable results over a wide temperature range, designed for both laboratory and field usage

- Verification standards are provided for daily accuracy check

- User calibration function for fine tuning accuracy for different operators

Data stored in memory and can be exported onto USB storage device - Battery powered

Consumables

- Part Number – 800-00070

- Description -Verification standards and vials for 500 samples

Combination Kits

FerroCheck 2000 is a great companion device when coupled with other portable oil analysis tools for different applications. Here are a few examples:

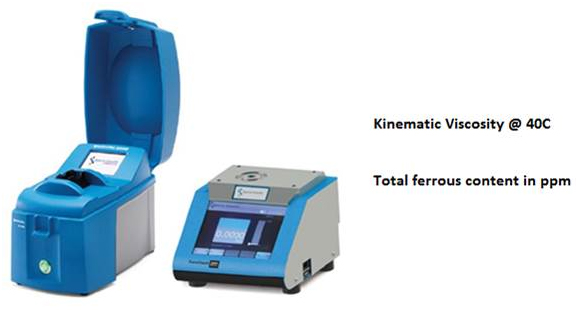

Basic Oil Analysis Kit

A quick check with viscosity and ferrous particle concentration in the field is the simplest way to make sure oil is good and machine wear is within alarm limits. With FerroCheck 2000, users can quickly check ferrous particle concentration up to 1%. It is a complimentary device to the SpectroVisc Q3000 and together they provide basic oil analysis for field service professionals.

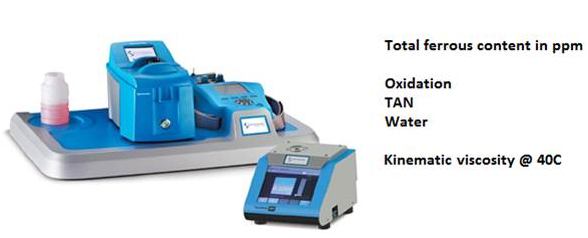

MiniLab 33 (FluidScan, Viscometer and FerroCheck Combo):

Basic Trivector™ MiniLab configuration that tests oil condition (Oxidation, TAN) with InfraRed Spectroscopy (FluidScan), Kinemetic viscosity @ 40C, liquid contamination (moisture) and ferrous content for abnormal wear. It is ideal for small- to medium-sized industrial or power plants looking to start an on-site oil analysis program.