040-23156400

sales@petrolabsindia.com

Historically, the analysis of grease has been confined to new grease testing for product acceptance and quality control. Technically, this was due to the sample size required to perform conventional ASTM (American Society of Testing and Materials) methods on grease samples. However, over the last couple of decades, new analytical methods have made it possible to profile the serviceability of grease using as few milligrams of sample as possible (0.00003527 of an ounce).

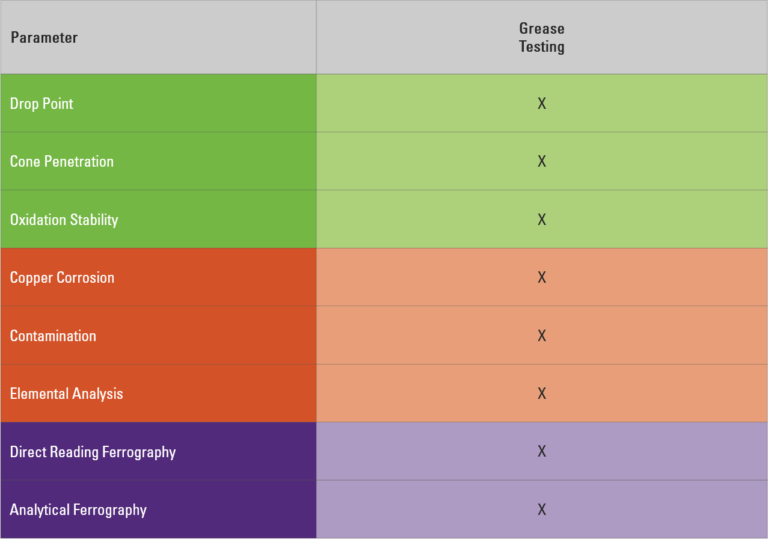

Grease-lubricated machines should be included in an effective condition monitoring program. At Petrolabs, we offer multi-faceted analysis to detect wear particles, contaminants and additives for in-service greases. Through routine sampling we are able to trend the data to identify potential problems before a major repair is required.

Wear metals are analyzed elementally via spectroscopic analysis to target the smaller, normal wear particles, and contrasted against Ferrous Wear Concentration which also detects larger, ferrous wear particles. Optionally, we may also perform Analytical Ferrography for determination of the wear mechanisms and severities of observable wear particles.

The additives are verified to ensure the correct grease is in use and not contaminated with another product. Contaminants, both particulate and water, are measured to determine when contaminants are increasing to a detrimental level.

© Copyright 2021 PetroLabs India Pvt. Ltd. All Rights Reserved. Design by Bhavya WebTech