040-23156400

sales@petrolabsindia.com

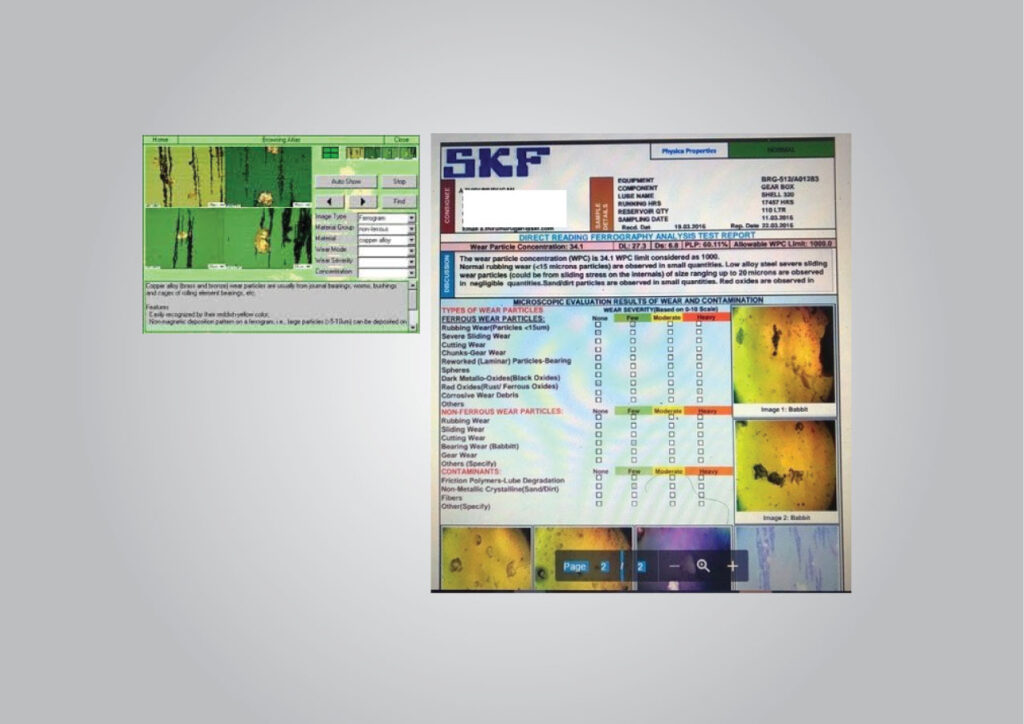

Analytical Ferrography is among the most powerful diagnostic tools in oil analysis today. When implemented correctly it is an excellent tool when attempting to diagnose an active wear problem. Analytical Ferrography allows an oil analyst to visually examine wear particles present in a sample. This test separates solid contamination and wear debris from a lubricant for microscopic evaluation. Analytical Ferrography can identify wear particles, their composition, and their origin by visually analyzing them microscopically.

This test is qualitative, which means it relies on the skill and knowledge of the ferrographic analyst. While this can have definite advantages, the interpretation is somewhat subjective and requires detailed knowledge of wear debris failure modes. The test procedure is also lengthy and requires the skill of a trained ferrographic analyst.

The test procedure is also lengthy and requires the skill of a trained ferrographic analyst

© Copyright 2021 PetroLabs India Pvt. Ltd. All Rights Reserved. Design by Bhavya WebTech